Gage Blog

Countersink Gage vs. Chamfer Gage “What’s the difference?”

When should a person choose a countersink gage over a chamfer gage? Ultimately they do a similar job: Both types of gages utilize a plunger and special ratio indicator to measure the top diameter of a tapered/countersink bore.

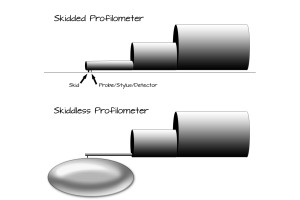

“Skidded” vs “Skidless” Profilometers

The typical application for a Profilometer is to measure the surface finish of a steel machined product to a very high accuracy. A measurement is separated into a number of cutoffs with a specified stroke length and even the most basic tester can usually measure accurately down to about 10Ra or .000010”.

Accuracy and Precision "You don’t want one without the other!"

If you put the search terms “Accuracy Definition” into Google you will be presented with the following result:

“the quality or state of being correct or precise” Read more

Measuring Flatness? Don’t make this mistake!

At Gaging.com LLC we do more than sell gages. We are also Metrology fans, geeks or whatever you would like to call us. So when we see the opportunity to perhaps provide a little clarity in our chosen field, we take it! Read more

Tolerances: “Do you know your limits?” Part 1

One of the most commonly asked questions we get at Gaging.com besides “Do you have it in stock?” is “What is the accuracy of the gage?” Read more

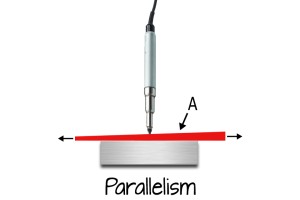

"Are your indicators and probes telling you the truth?"

Often times a customer will simply mount his or her indicator/probe into comparator stand, set zero and start taking measurements. Read more

Quality vs. Accuracy needs: “How much do I have to spend?”

A common need in road paving operations is the ability to measure the crown of the road while the surface is being laid. The crown is basically a slight bulge in the center of the road to ensure that rain water drains off on either side instead of pooling on the road surface and creating a driving hazard. Read more

Types of Certification Available for Thread Gages

A frequently asked question we receive at Gaging.com is: "What type of certification is offered for thread gages?" Normally gage manufacturers today (PMC Mercury, Hemco, Vermont Gage, Meyer Gage) offer three types of certifications for thread gages Read more

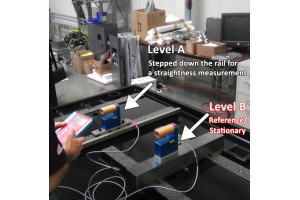

“Differential Leveling, it’s just A-B!”

Differential leveling is often misunderstood and made more complicated than necessary. It is essentially as easy as A-B and critical to high precision straightness (line) or flatness (surface) measurements. Keep in mind when we talk of straightness or flatness we are not talking about the angle the surface is sitting at compared to the center of Earth’s gravity. While it is better to have the surface as “level” as possible before conducting a flatness measurement for several reasons, it is not the same thing as flatness. Flatness is concerned with the overall error (usually expressed as a height) from the lowest to highest point of the measured surface. Read more

“What does the IP rating on my Caliper mean?”

At Gaging.com electronic gages now far outsell their analog/vernier counterparts. From time to time we still hear the old timers opine about how great their old school gages are but there is no denying the accuracy, speed and ease of use of a modern digital gage. Digital micrometers, Digital Calipers, Digital Bore Gages, Digital Levels, they are all here to stay but they did have a modest start. The first generation of digital gages had very little protection when it came to environmental or shop contaminates. Read more