If you put the search terms “Accuracy Definition” into Google you will be presented with the following result:

“the quality or state of being correct or precise”

That is true, but when looking at it from a Metrologist’s standpoint the second definition is more correct:

“The degree to which the result of a measurement, calculation, or specification conforms to the correct value or a standard.”

So what is wrong with the first statement? It is the use of the word precise. I will briefly go over the differences between Accuracy and Precision (aka Repeatability).

People assume ACCURACY is the most important characteristic of measuring equipment and I am not disagreeing with them. However, an accurate gage is not necessarily the same thing as a repeatable or precise gage.

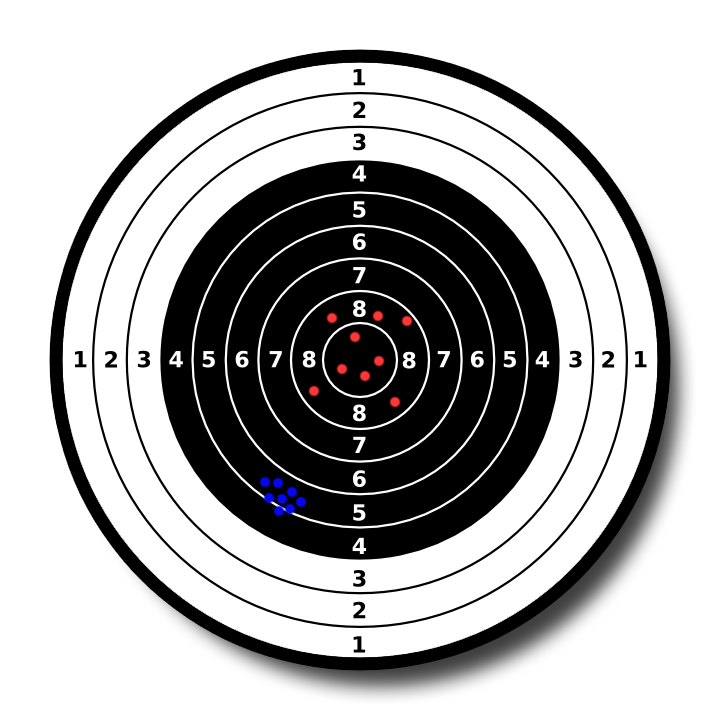

Take a look at the image below that has been used in a similar fashion in many textbooks. It uses a target with bullet holes in it to represent some type of gage taking measurements on a test piece. You could also use a shuffleboard, dart board or similar to show the comparison.

The Red Grouping shows a pattern closer to the center of the target or true value of a test piece, hence a more “accurate” result.

The Blue Grouping shows a less accurate result because it is farther away from the center of the target (or desired measurement) but the pattern is much tighter. This represents a more PRECISE or REPEATABLE gage.

From a Metrologist’s standpoint if the equipment that produced the Blue Grouping can be calibrated/adjusted to correct accuracy problem i.e. datuming a height gage on a surface plate, cleaning the jaws of a caliper, remastering a bore gage in a setting ring or adjusting the sleeve of a micrometer with a mic wrench, it is simply the better gage.

Please let us know if you have any questions or comments. MEASURE SMARTER!

Comments

Leave a Comment

Leave a Reply