The typical application for a Profilometer is to measure the surface finish of a steel machined product to a very high accuracy. A measurement is separated into a number of cutoffs with a specified stroke length and even the most basic tester can usually measure accurately down to about 10Ra or .000010”.

We have dealt with hundreds (maybe more) surface finish applications over our decades of metrology experience and they can vary greatly. We have measured non-woven fabric materials, concrete floors, pickleball paddles and many other “unusual” surfaces.

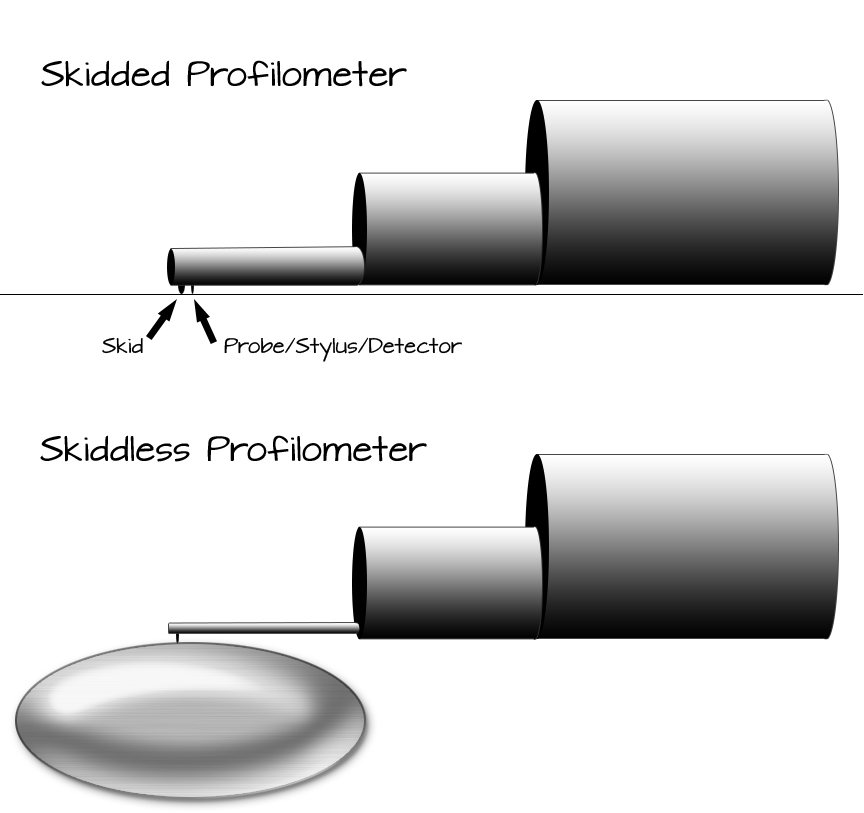

One commonly asked question is what type of profilometer do I need? What we recommend depends on what surface you are trying to measure and to what accuracy. So back to the title of the Blog Entry: “Skidded” vs “Skidless” Profilometers. What is the difference and what do I need to know?

To put it simply, a skidded profilometer requires a flat measuring surface to produce accurate data and a skidless profilometer can measure accurately on both flat and radiused surfaces.

How do you tell the difference?

A skidded proflimeter uses a styli/detector/probe that has a small skid or “foot” that travels along with the probe so the actual surface being measured is the reference. Often times the skid is built into the housing that covers the probe and can be in front of or behind or next to the stylus. A skidded profilometer is usually priced much lower than its skidless counterparts, typically in the $1,000 to $3,000 price range and not as sophisticated.

Some popular Skidded models: 54-410-500 Fowler X-Pro, SRG-2000 by Phase II+, SR-160 by Starrett, EMD-1500-311/2191800 Mahr Pocketsurf, 178-561-02A Mitutoyo SJ-210

On skidless models you will basically see a bare styli/detector/probe with no skid accompanying its movement. They can measure radiused surfaces and have the math functions built into the tester to separate the waviness measurement from the roughness. They typically start at around $7,000.00 dollars and are less portable, usually in a lab or inspection environment.

Some popular Skidless models: 178-581-02A Mitutoyo SJ-410, 06930012 Brown and Sharpe Rugosurf

4 Comments

Leave a Comment

Leave a Reply